INDUSTRIAL ABRASIVE BLASTING SERVICES

NASCO: CONTROLLED SURFACE PREPARATION, THE FOUNDATION OF EVERY SUCCESSFUL COATING

Up to 80% of coating failures begin before the first coat is applied.

The cause is almost always improper surface preparation.

At NASCO, we’ve spent over 35 years preparing metal surfaces the right way — inside a controlled indoor blast booth, using the correct media and technique for each application, and taking on the parts most shops won’t touch.

If your coating needs to last years instead of months, surface preparation isn’t optional. It’s the foundation everything depends on.

WHY INDOOR CONTROLLED BLASTING MATTERS

Not all blasting is equal.

We blast indoors in a controlled environment. That control directly impacts coating performance and long-term durability.

What we eliminate:

• Weather contamination

• Humidity swings and flash rust

• Airborne dust settling on clean metal

• Inconsistent blast conditions

• Media quality loss

What that means for you:

• Consistent anchor profile

• Clean metal that stays clean before coating

• Reduced flash rust risk

• Predictable, repeatable results

• Stronger long-term adhesion

You can have perfect blasting technique — but if the surface gets contaminated before coating, it doesn’t matter. Controlled indoor blasting protects your investment from start to finish.

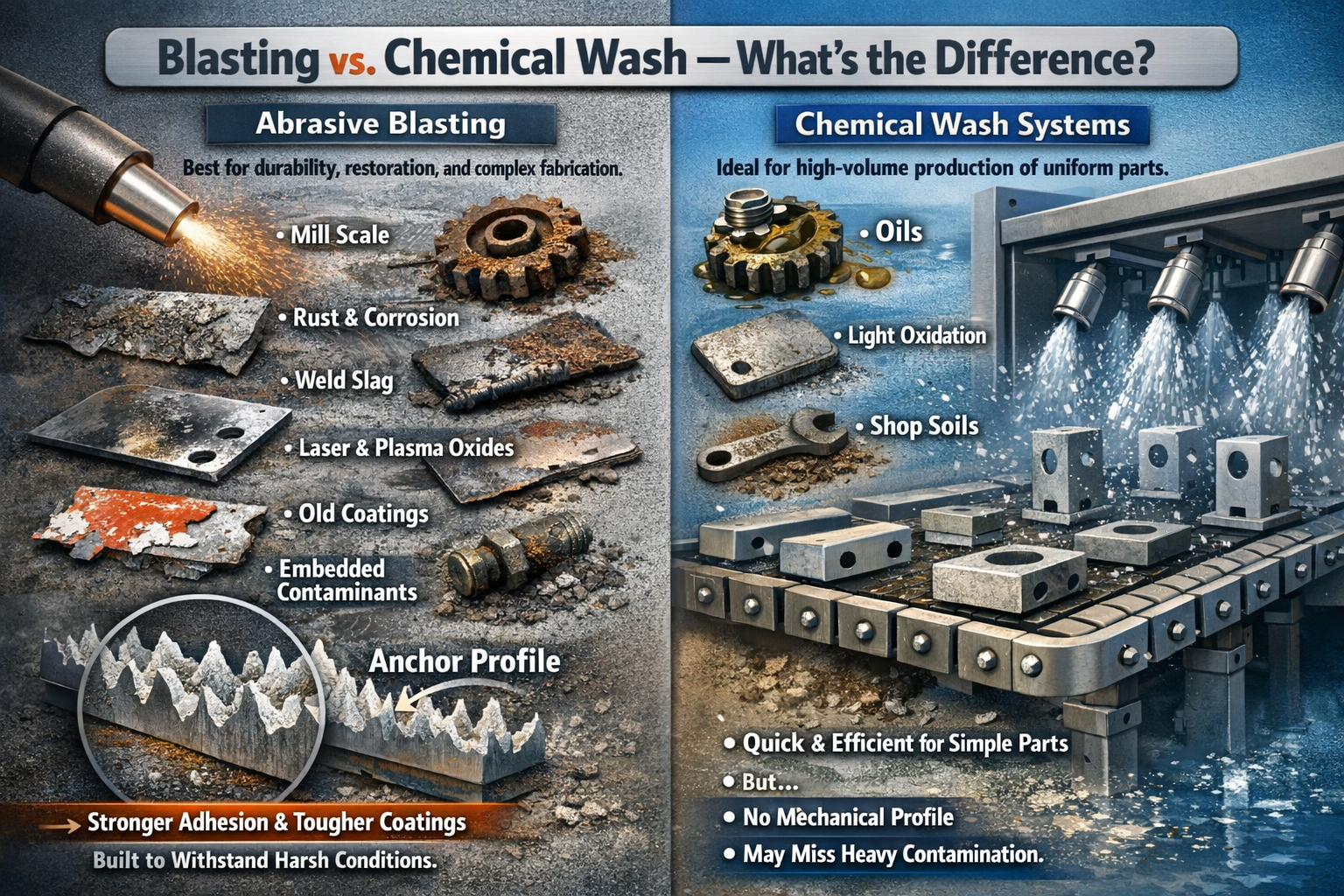

WHAT WE REMOVE (AND WHY IT MATTERS)

Blasting removes what chemical wash systems cannot:

• Mill scale

• Rust and corrosion

• Weld slag and spatter

• Laser and plasma oxides

• Previous coating systems

• Embedded contaminants

We don’t just make it look clean.

We make it coating-ready.

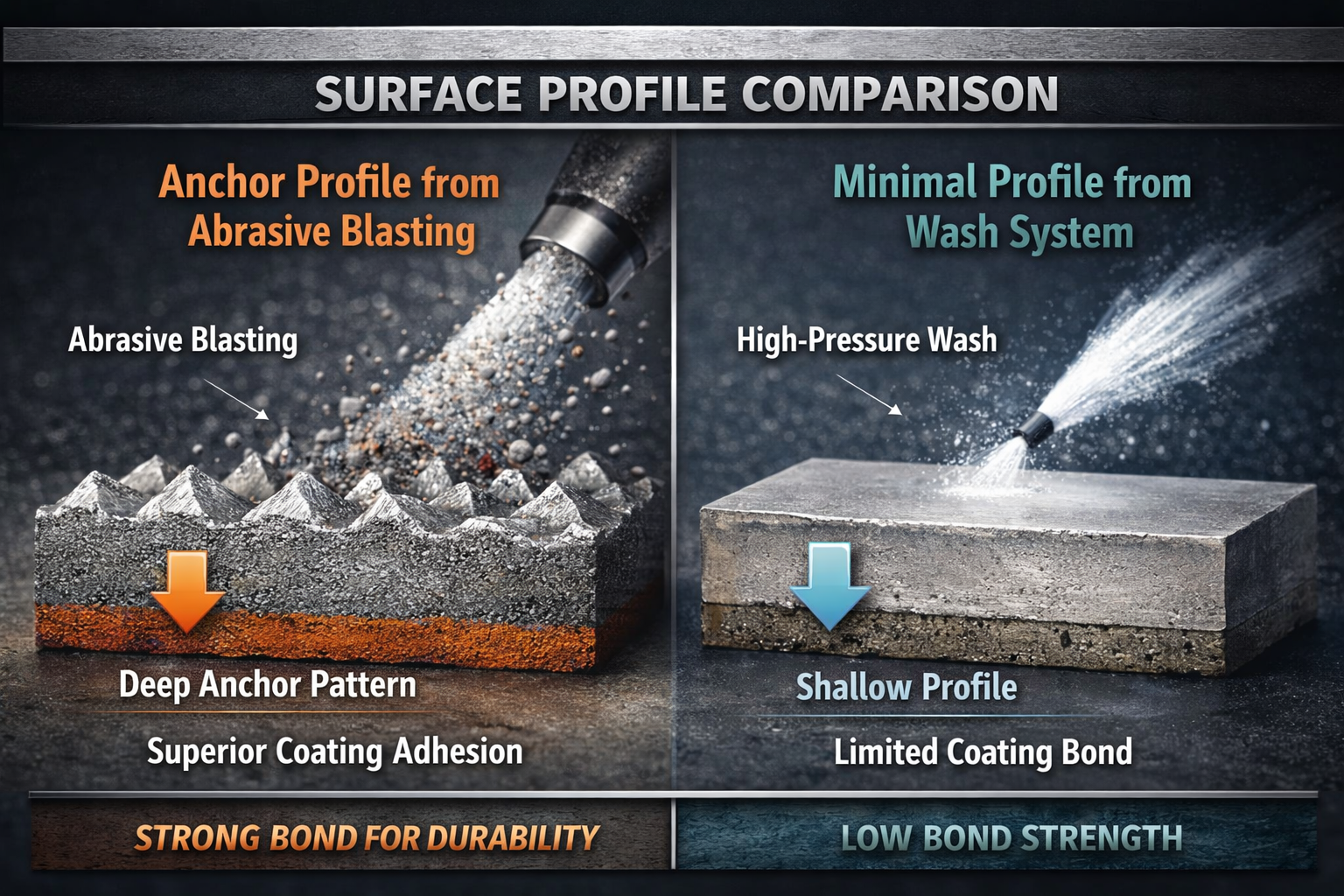

SURFACE PROFILE: THE DIFFERENCE BETWEEN “COATED” AND “PROTECTED”

Blasting isn’t just cleaning — it creates an anchor profile.

That microscopic pattern of peaks and valleys allows coating to mechanically lock into the surface.

Without proper profile, coating relies only on chemical adhesion.

With proper profile, coating interlocks into the steel.

Proper profile delivers:

• Stronger adhesion

• Improved chip and impact resistance

• Longer service life

• Reduced maintenance cycles

• Better performance in harsh environments

Typical profile ranges:

• Powder coating: 1.5–3 mils

• High-build liquid coatings: 2–4 mils

• Zinc-rich primers: 2–3 mils

We match media, pressure, and technique to your coating specification — no guesswork.

GLASS BEAD BLASTING FOR STAINLESS STEEL

Not every blast job is about coating preparation.

Glass bead blasting creates a uniform satin finish on stainless steel — often serving as the final finish with no coating required.

Unlike aggressive angular media, glass bead peens the surface to create a consistent matte appearance while maintaining corrosion resistance.

Ideal for:

• Food processing equipment

• Architectural stainless components

• Medical and pharmaceutical equipment

• Commercial kitchen equipment

• Industrial stainless fabrications

Benefits:

• Uniform satin finish

• No coating required

• Maintains corrosion resistance

• Hides minor imperfections

• Clean, professional appearance

MEDIA SELECTION: PRECISION, NOT ONE-SIZE-FITS-ALL

Different materials and coatings require different media.

We select abrasive based on:

• Substrate material

• Required profile depth

• Geometry and complexity

• Coating system requirements

• End-use environment

Primary media:

Aluminum Oxide – aggressive and recyclable, ideal for heavy contamination and coating prep

Garnet – efficient cutting with uniform profile, excellent for near-white specifications

Glass Bead – satin stainless finishing

Specialty media – for unique or sensitive applications

The wrong media can damage parts or compromise coating performance. Experience matters.

WHAT WE BLAST

Heavy Industrial & Fabricated Steel

• Structural steel assemblies

• Heavy equipment components

• Process equipment

• Material handling systems

Coating Preparation

• Powder coating prep

• Zinc-rich primer prep

• Epoxy and polyurethane systems

• High-performance liquid coatings

Restoration & Rework

• Failed coatings

• Severe corrosion

• Parts rejected by production shops

Stainless Steel Finishing

• Architectural stainless

• Food-grade components

• Fabricated enclosures

• Equipment assemblies

If it’s heavy, oversized, complex, or “too difficult” for a conveyor-based shop — that’s where we operate.

SSPC / NACE STANDARDS COMPLIANCE

We work to recognized industry standards, including:

• SSPC-SP 10 / NACE No. 2 – Near-White Metal Blast

• SSPC-SP 6 / NACE No. 3 – Commercial Blast

• SSPC-SP 5 / NACE No. 1 – White Metal Blast

• SSPC-SP 14 / NACE No. 8 – Industrial Blast

When specifications call for documented cleanliness and profile, we deliver measurable, repeatable results.

No guessing. No “close enough.”

BLASTING VS. CHEMICAL WASH

Chemical wash systems are effective for:

• High-volume production parts

• Light oils and shop soils

• Simple geometries

Abrasive blasting is required for:

• Mill scale and rust

• Heavy oxidation

• Complex weldments and assemblies

• Harsh service environments

• Restoration and recoating

• Applications requiring mechanical profile

If coating performance matters, blasting delivers results chemical cleaning cannot.

THE COST OF POOR SURFACE PREPARATION

Industry data shows 75–80% of premature coating failures stem from inadequate surface preparation.

Failure leads to:

• Chipping and peeling

• Blistering and corrosion under film

• Disbondment under stress

• Complete recoating at full cost

You cannot coat your way out of poor preparation.

Do it right once.

LET’S TALK ABOUT YOUR PROJECT

Phone: 519-432-8346

Email: info@nasco1.com

Location: London, Ontario

Website: www.nasco1.com

We’re happy to:

• Review coating specifications

• Evaluate problem parts

• Discuss SSPC requirements

• Quote oversized or complex assemblies

• Advise on stainless finishing

Problem parts welcome! If another shop said no , we’d like to hear about it.